Sculpture

For 25 years I have made over 500 life size stoneware sculptures, each hand crafted with Laguna Red Wing (WC837) stoneware clay,

and fired in my 20 cubic foot downdraft propane kiln.

Shown here are the three remaining works I am still willing to produce.

Special order, allowing

for a three month production time. Local deliveries only, since shipping charges have become prohibitive.

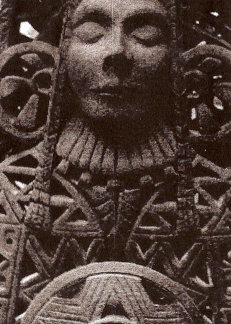

⇧ “Shemana” ©1997

Life size pond fountain.

Stoneware clay.

Shemana is a name representing the Medicine Woman.

⇧ “Toltec” ©1987

Butterfly Knight sculpture.

Stoneware clay.

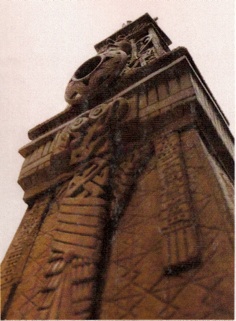

⇐ “Electra Obelisk”©1990

Detail of life size stoneware sculpture. Contains on the body the 20 Mayan Day Glyph Codexes, the four directions.

Facial elements of this sculpture are contained in the drawing: “The Rose Line.”

The work captures through its mass the link with

Mother Earth, revealing the meaning of the matrix of the planetary grid.

Stoneware is a 5,000 year old kiln firing process imposing extreme temperatures on clay ornaments in excess of 2,300℉. This technique had its origins in Mesopotamia. The glazes are absolutely fixed into the vitrified product and these objects are estimated to last thousands of years, as manufactured stone.

My work is part of the fossil record. This is exemplified in the drawing “The Cost of Freedom” showing both my raku and stoneware efforts in the shard pile.

The Hopi and Maya cultures hold the thought that consciousness is infused into any object made by hand. These are then played back using psychometry.

Living audio tapes!

⇐“Deerman” ©2004 Stoneware sculpture bust. Using living antlers, mesquite base.

“Electra Obelisk” ⇒

©1990.

The shot reflects the mass of the sculpture.

Hand built in 1983, this kiln is a product of years of building, research and use to get the greatest amount of usable volume and efficiency from the largest space allowed for a residential setting, which is 20 cubic feet.

The kiln is of a variety called s sprung arch downdraft, utilizing two hand made forced air burners for the firing. There is no chimney stack, since the burners are forced air, the firing being tuned with dampers built into the blowers. There are no bag walls to take up space.

Shown here approaching maturity of 2,300℉, the kiln is fired for fourteen hours starting at midnight, consuming 40 gallons of propane to reach that temperature. There are two hour long episodes of reduction procedures, the first leaving a beautiful toasted finish to the body of the work, at 2,000℉, and the second to bring out the stony luster of the glaze, at 2,250℉. This is accomplished by damping the burners and creating a rich burn, emitting a green flame from the chimney vent, at the back of the kiln. A firing takes 2 days to cool.