Raku Pottery

Raku is an ancient Japanese process that metaphorically illustrates enlightenment through purification. Involves porcelain cups that are fired red hot in a kiln and then tong lifted into smoldering tea leaves and dowsed in drinking water. The tea is then consumed.

⇧ Over 3,000 raku pots have passed through these hands, from 1978 to 2009. All have been hand thrown on the potter’s wheel. Either with a Shimpo electric or a Lockerbie kick wheel, and ranging in thrown size from a few pounds to 75 pounds each, to a height of 24.” All pots are bisque fired in an electric kiln, coated with 80% colemanite/ 20% feldspar glaze, and a CuCO3 wash, and then fired in a handmade oil drum kiln lined with ceramic fiber using propane for fuel. The work is lifted red hot and placed in a covered galvanized can of sawdust until cold. Poof! The spectacular results include an array of crackles in the glaze surface and a rainbow of colors from the copper carbonate’s chemical reduction. The range of products I make are made at my personal pleasure, due to health reasons.

⇧“Mayan Incensario Jar.” ©2005. Illustrating the Maya Peyote Vision Serpent scene of Lady Sextun and Yaxchilan. Yet another metaphor of transcendence.

Earthenware fired to a temperature of

2,000℉, inside a fiberfax lined oil drum. ⇓

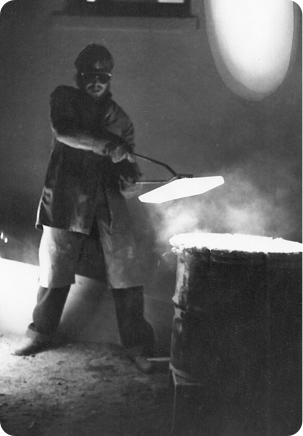

The drama of raku is demonstrated in

this old B/W action photo of me, taken during tenure as director of the Tucson Parks and Recreation Pottery Department.

The brilliant object being lifted is a kiln shelf,

2,000℉, emitting incandescence...

red hot and spitting fire and brimstone! ➩

Anatomy of the Incensario Jar:

From start to finish: left to right, top to bottom, the wedged 25# block of clay on the potter’s wheel is centered. Then the donut hole is forced through the centered mass and opened and pulled upward and out. The cylinder is then dried to leather hard, trimmed, and inscribed with the pattern to be carved. The pattern is hollowed through and surface treatments are finished, revealing the design called “El Habla Calavera”. The last image is of the chimney set over the peyote bowl.

Raku firing process, from start to finish. First, the glazed bisque ware is placed in the oil drum kiln on a shelf, with the bowl on the lower shelf. The contents are covered and the burner is lit.

The kiln is fired with propane to 2,000℉. In about an hour, the pottery is removed from the red hot kiln with tongs and placed into a vat of sawdust. This turns the bare clay black, and renders the glazed areas with an antiqued crazed or crackled finish.

The finished product, “El Habla Calavera” Incensario Jar.

⇐ Large one piece raku amphora. When it was fired, it was lifted from the kiln red hot quickly with my gloved hand, no tongs, it was too big!